1. Industrial Automation: Conveyors, SPMs, Stations, All Type of Material Handling Equipments

Design of Automated Systems

Design of Mechanical Systems

Equipment Modification and Optimization

Post-Design Assembly

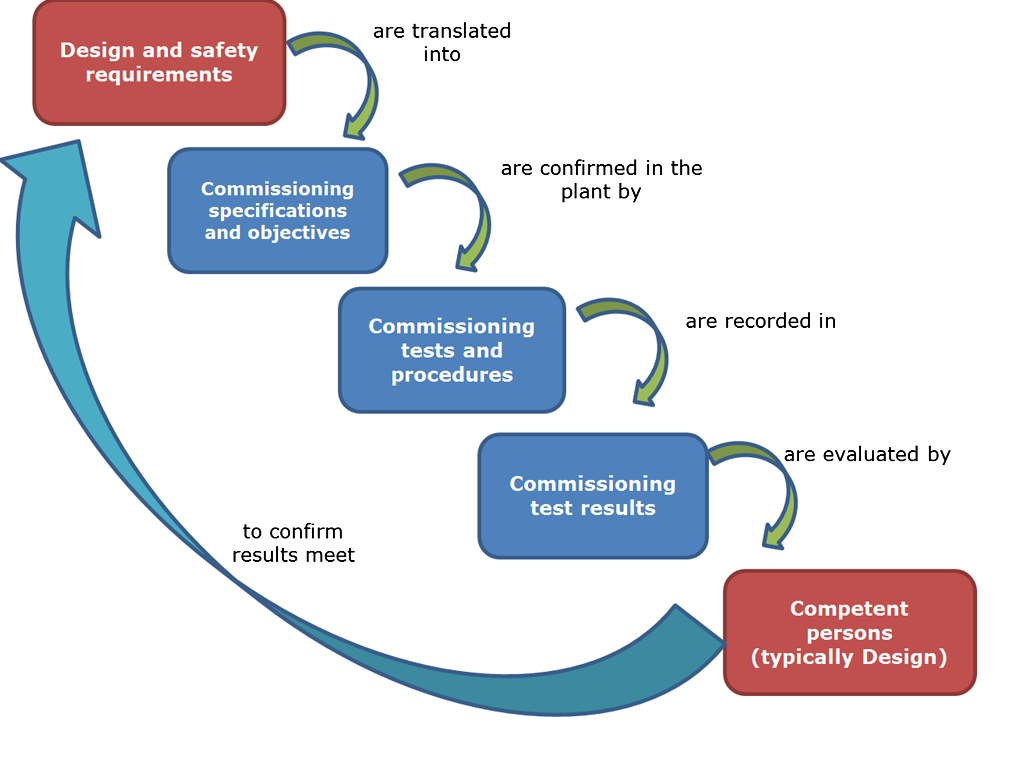

Quality and Functionality Validation - Testing

Installation, Commissioning and Start-Up on Production Site

2. Robotic Cells

Robotic Cell Design

Robotic Tools Design

Assembly, BIW and Gauging Fixture

Features