Project categories

Preliminary and Detailed Engineering

Control Panel Manufacturing

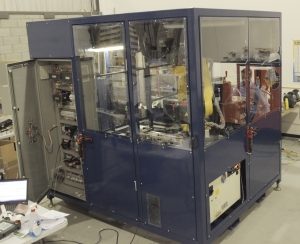

Research and Development - Prototypes

Risk Analysis – Machine Safety

Project Management

Installation & Commissioning

Consulting

Achievements